ENIG Nickel Corrosion on Wetting Balance Test Results and Intermetallic Formation

This paper attempts to further clarify the effects of nickel corrosion on solder wetting balance test results and the resultant intermetallic formed.

Analysis Lab

DOWNLOAD

|

Authored By:

Donald Gudeczauskas, George Milad

Uyemura International Corporation

CT, USA

Summary

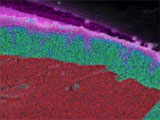

Since the IPC-4552 rev A for ENIG was introduced there have been many requests for clarification of acceptable and unacceptable levels of nickel corrosion. This paper attempts to further clarify the effects of nickel corrosion on solder wetting balance test results and the resultant intermetallic formed. The study will attempt to produce level 1, level 2, and level 3 corrosion as denoted by IPC-4552 rev A and tabulate wetting balance results and congruity of intermetallic formed.

Conclusions

Increased dwell time in the immersion gold alone did not produce rejectable product. Solution agitation did not influence the degree of corrosion overall although on a micro scale it may have given localized corrosion on the leading edge of solution flow. The type of gold showed differences in nickel corrosion as evidenced by the cross-section analysis. Under the most aggressive dwell time with the more aggressive gold bath “A” occasional Level 2 and level 3 corrosion was found. The occurrences and frequency of these levels of corrosion were not enough to classify the product as “Rejectable”. It is worth noting that the “Reduction Assisted” immersion gold “C” showed no level 2 or level 3 corrosion on any of the cross-sections that were evaluated, regardless of dwell time and final gold thickness.

Initially Published in the SMTA Proceedings

|

Comments

|

No comments have been submitted to date.

|

|

|

|